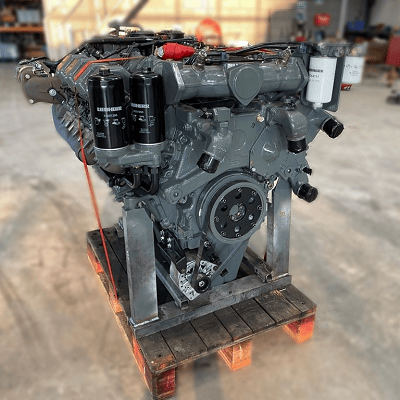

The process of a dyno test on a Liebherr engine

When it comes to heavy machinery, reliability and power are paramount. Liebherr, a name synonymous with innovation and excellence in engineering, stands tall as a pioneer in the realm of heavy equipment and machinery. From towering cranes to robust excavators, Liebherr’s engineering prowess extends to the heart of these machines. We delve into the world of dyno testing a Liebherr engine, uncovering the meticulous process behind unleashing the raw power concealed within.

The foundation of excellence

Before we embark on the journey of dyno testing, it’s crucial to understand the foundation upon which Liebherr engines are built. With decades of engineering expertise and commitment to quality, Liebherr engines are crafted to withstand the most demanding environment and deliver unparalleled performance. Each component is meticulously designed and rigorously tested to ensure reliability, efficiency and longevity.

The process

1 Preparation: The engine undergoes meticulous preparation before being mounted onto the dynamo meter. This includes ensuring all connections are secure, fluids are filled to the appropriate levels, and sensors are properly calibrated.

2 Mounting: The engine is carefully mounted onto the dynamometer, a specialized device designed to simulate real-world operating conditions. Precision is paramount during this step to ensure accurate results.

3 Initial checks: Once mounted, a series of initial checks are conducted to verify proper alignment, connection integrity, and functionality of all engine systems.

4 Warm-up: The engine is started and allowed to warm up to operating temperature. This ensures consistent results and minimizes the risk of damage during testing.

5 Baseline testing: With the engine warmed up , baseline tests are conducted to establish initial performance metrics. This includes measuring power output, torque, fuel consumption, and emissions at various RPM levels.

6 Load testing: The engine is subjected to progressively increasing loads to simulate different operating conditions, such as idle, partial load and full load. This allows engineers to assess performance across the entire operating range and identify any potential issues or optimization.

7 Data analysis: Throughout the testing process, data is continuously collected and analyzed in real-time. Advanced instrumentation and software are used to monitor performance metrics and identify trends or anomalies.

8 Optimazation: Based on the data analysis, adjustments may be made to optimize engine performance. This could involve fine-tuning fuel injection timing, adjusting air-fuel ratios, or optimize turbocharger boost pressure.

9 Validation: Once testing is complete, the results are meticulously reviewed and validated against predetermined criteria and specifications. Any deviations or anomalies are thoroughly investigated to ensure accuracy and reliability.

10 Reporting: Finally, a comprehensive report is generated detailing the results of the dyno testing, including performance metrics, observations, and any recommendations for further optimization or refinement.

The outcome of dyno testing

Dyno testing a Liebherr engine is more than just a routine procedure – it’s a testament to the unwavering commitment to excellence that defines Liebherr’s engineering philosophy. By subjecting their engines to rigorous testing and analysis, Liebherr ensures that each engine delivers the uncompromising performance, reliability, and efficiency that customers expect.

In conclusion, dyno testing a Liebherr engine is not just about measuring power output. It’s about unlocking the true potential of these remarkable engines and ensuring they exceed expectations in the most challenging environments imaginable.

Pipe Injection Molding Machine

-

Precision Manufacturing:

- The machine is capable of injecting molten PVC into molds with extreme accuracy, ensuring consistent wall thickness and dimensions for the water pipes.

- The molds are designed specifically for PVC pipes, providing optimal cooling and hardening processes to produce pipes with high durability.

-

High Efficiency:

- The injection molding process is automated, minimizing manual labor and reducing production time.

- The machine can handle multiple molding cycles simultaneously, allowing for faster output of PVC water pipes.

-

Versatility:

- The PVC Water Pipe Injection Molding Machine can be configured to produce pipes of different diameters, thicknesses, and lengths.

- It can also accommodate different types of PVC materials, depending on the application requirements.

-

Energy Efficiency:

- The machine is designed to minimize energy consumption during the injection molding process, reducing operating costs.

- It also features energy-saving modes that can be activated during periods of low production.

-

Ease of Maintenance:

- The machine is built with easy access to critical components, allowing for quick and simple maintenance and repairs.

- It also comes with detailed maintenance manuals and support from manufacturers, ensuring continued optimal performance.

Advantages:

-

Cost-Effectiveness:

- The PVC Water Pipe Injection Molding Machine provides a cost-effective way to produce large quantities of PVC water pipes.

- It reduces material waste and rejects due to its precision and repeatability.

-

High-Quality Products:

- The pipes produced by this machine exhibit superior strength, durability, and chemical resistance, making them suitable for a wide range of applications.

-

Scalability:

- The machine can be scaled up or down depending on production demands, allowing manufacturers to flexibly meet changing market requirements.

-

Environmental Friendliness:

- PVC is a recyclable material, and the injection molding process produces less waste compared to traditional manufacturing methods.

Large Tray Making Machine,Injection Molding Machine Of Pipes,Ppr Gas Pipe Fittings,Fittings For Ppr Pipe

Ningbo Outai Plastic Machinery Technology Co.,Ltd , https://www.outacmachine.com