I. Introduction

Laser cutting technology is designed to utilize high-energy laser beams to cut any materials. This technology leads the laser beam via optical and computer numerical control systems (CNC).

It uses a movement control system to track the patterns on the materials to be cut based on CNC or G-code. Laser cutting can achieve high-precision cutting, and is suitable for various materials like aluminum.

Aluminum and aluminum alloy materials are widely used in multiple spheres like aerospace, automobile manufacturing, and electronic communications due to their prominent properties like lightweight, good conductivity, and corrosion resistance.

Laser cuts aluminum can produce intricate aluminum components precisely and efficiently.

However, aluminum has a strong reflectivity towards laser beams and also has high thermal conductivity, which brings some troubles to some extent to aluminum cutting.

Therefore, knowing the processability and restrictions of laser cutting aluminum is of paramount importance for aluminum manufacturing and production.

This may not only involve the understanding of techniques but also the cognition towards aluminum alloy properties, as well as how to overcome the challenges during the cutting.

II. Understanding Aluminum as a Material

Physical properties of aluminum

Aluminum is a material that possesses many kinds of physical properties. It is a solid, nonmagnetic, matte, and silver-white metal with a slight blue tint.

The surface of aluminum is highly reflective and features a face-centered cubic structure, which is stable before melting.

The density of aluminum is low, non-toxic, has high thermal conductivity, and excellent corrosion resistance, which can easily be manufactured, fabricated, and shaped.

What’s more, aluminum has good ductility and plasticity, which can be torn to lines or rolled into thin foil.

Common applications of aluminum in various industries

Aluminum is widely applied in multiple spheres. For example, aluminum can be used in the construction area to produce window frames, curtain walls, roofs, cladding, structural elements, and interior components.

In the food and pharmaceutical industry, large parts of aluminum are used to package food, drugs, and beverages because it will not affect the smell of the food, and keep and repel moisture.

Why aluminum is a popular choice for laser cutting projects

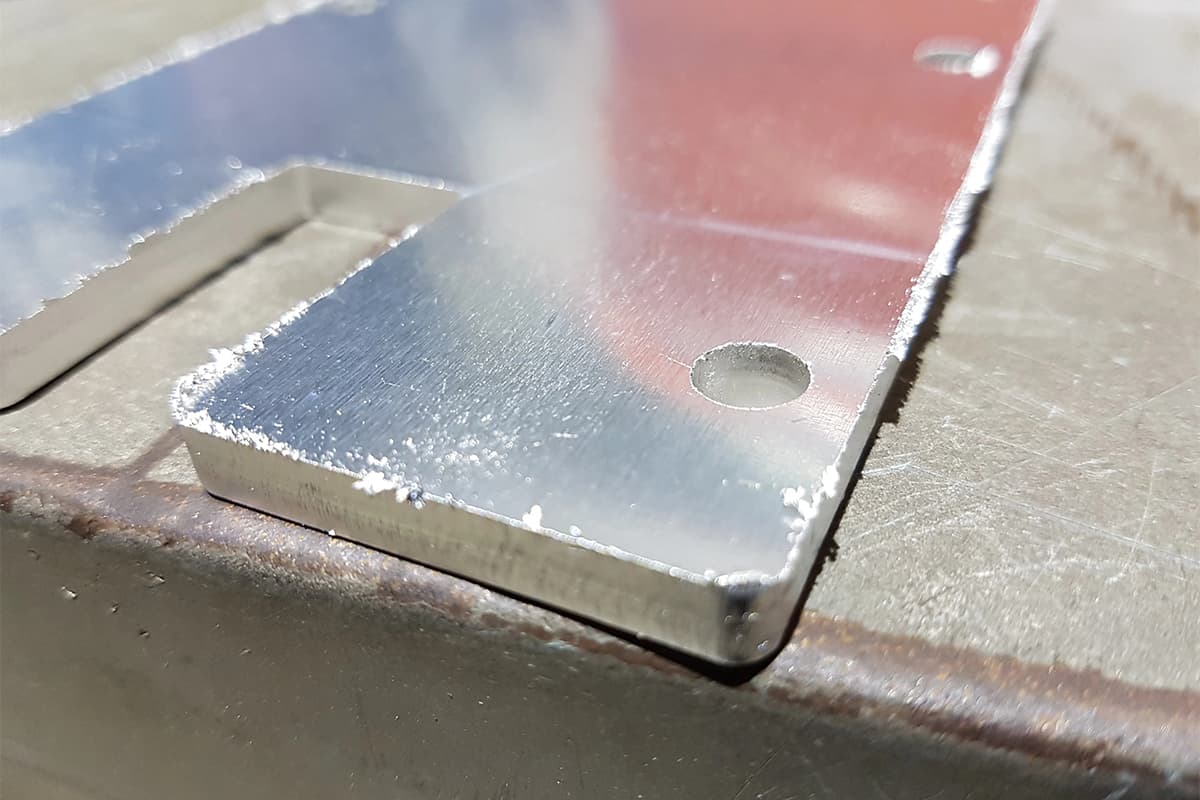

The reason for aluminum to be chosen for laser cutting programs is that its soft and plastic molecular structure makes the laser not penetrate utterly.

The high thermal conductivity means that it can quickly absorb the energy from the laser, which is beneficial to create clean cuts with no burrs, or minimum burs.

Despite this, laser cutting aluminum is not easy, it requires special techniques and equipment to handle the high thermal conductivity and optical reflectivity of the material.

Through using different levels of aluminum (like 6061, 5052, 5083, and 7075), laser cutting technology can process it efficiently to meet specific needs.

III. Can Laser Cutters Cut Aluminum?

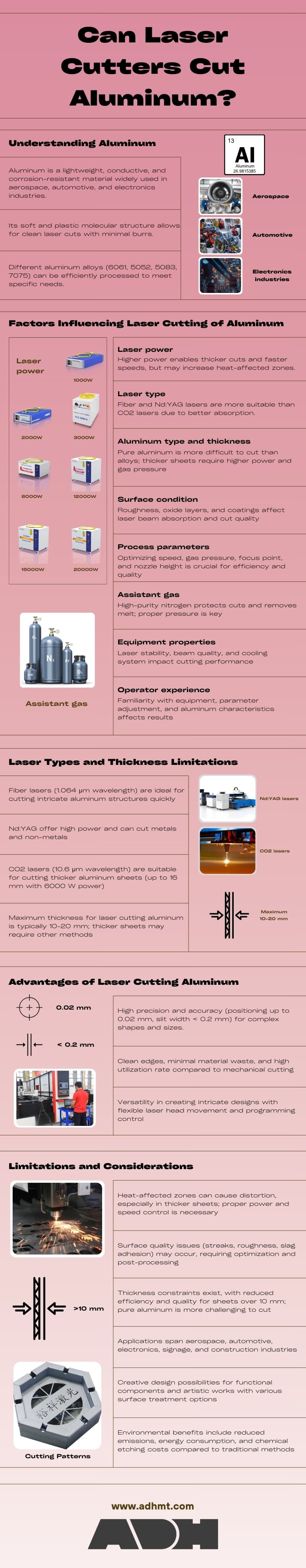

Factors influencing the ability to cut aluminum with laser technology

Laser power

Laser power is the key factor in determining the cutting thickness and speed. The bigger the power, the thicker the cutting thickness, and the faster the cutting speed.

However, over-high power may lead to heat heat-affected zone increasing, affecting the cutting quality.

Laser type

Fiber lasers and Nd: YAG lasers are more suitable for cutting aluminum than Co2 lasers because their wavelength is easier to absorb.

The quality of fiber laser is high, and process efficiency is high, which is an ideal choice for cutting aluminum.

Aluminum type and thickness

Pure aluminum is extremely difficult to cut owing to its high reflectivity, and aluminum alloy has better cutability.

Different aluminum alloys’ chemical components and thicknesses may also affect the laser cutting properties. A thick aluminum sheet may need higher laser power and gas pressure.

The surface state of aluminum

The roughness, oxide layers, and coatings on the surface of aluminum may affect the absorption and cutting effect of the laser beam. If the surface is not treated well, the cutting side quality will decrease.

Cutting process parameters

The optimization of process parameters like cutting speed, gas pressure, focus point location, and nozzle height, are pivotal for aluminum cutting quality.

Proper parameters can acquire higher cutting efficiency and better quality of the cutting side.

Assistant gas

High-purity nitrogen is the common assistant gas for aluminum cutting, which can protect the cuts and take away the melt.

Low gas pressure will decrease the quality of cuts, and higher pressure will produce eddy currents on the surface of the material.

Laser-cutting equipment properties

The equipment properties like laser stability, laser beam quality, and cooling system leave an important influence on the cutting effect.

Laser cutting equipment with high properties can offer more excellent cutting ability.

Operator experience

The operator's familiarity with the equipment, ability to adjust process parameters, and understanding of aluminum cutting characteristics will all affect the final cutting effect.

Thickness limitations for laser cutting aluminum

The laser cutting machine’s power is the key to determining the cutting thickness. The bigger the power, the thicker the aluminum sheet that can be cut.

500W fiber laser cutting machine can cut aluminum sheets up to 2 mm thick.

1000W fiber laser cutting machine can cut the aluminum sheet up to 3 mm thick.

2000W fiber laser cutting machine can cut the aluminum sheet up to 5 mm thick.

3000W fiber laser cutting machine can cut the aluminum sheet up to 8 mm thick.

6000W fiber laser cutting machine can cut the aluminum sheet up to 16 mm thick.

The CO2 laser cutting machine with 5.7 KW power can cut industrial pure aluminum with a maximum thickness of 12.7 mm, and the cutting speed can be up to 80 cm/min.

Generally speaking, the maximum thickness of the laser cutting machine that cuts the aluminum sheet is between 10-20 mm.

The aluminum sheet over 20 mm thickness is recommended to use other cutting methods.

The type of aluminum sheet also affects the cutting properties. Pure aluminum is more difficult to cut than aluminum alloy.

The cutting surface roughness of aluminum alloy with high alloying element content is small.

Types of lasers suitable for cutting aluminum

Fiber laser

Fiber laser is one of the most appropriate lasers to cut aluminum sheets. Its wavelength is 1.064 microns, and easier to be absorbed by aluminum material than CO2 lasers.

The density of fiber laser power is high, and the spot size is small, laser beam quality is good, which can fastly cut the intricate aluminum structure quickly. The lifespan of fiber lasers is long, and maintenance costs are low.

Crystal laser

Crystal lasers like Nd: YAG and Nd: YVO4 are also suitable for cutting aluminum sheets. They are similar to fiber lasers, and their wavelength is 1.064 microns.

The power of crystal lasers is high, which can cut metals and non-metal materials. However, crystal laser pump diodes are expensive and have a shorter lifespan than fiber lasers.

CO2 laser

A CO2 laser is also a proper choice for cutting thicker aluminum sheets. Its wavelength is 10.6 microns, output power is higher, which is suitable for cutting large areas of thick materials. For example, 6000W CO2 lasers can cut 16 mm thickness aluminum sheets. However, the reflectivity of the Co2 laser is high when cutting the aluminum plates. The “reflection absorption" device needs to be installed on the system to avoid spoiling the optical components.

Excimer laser

Excimer laser emits UV light, and the wavelength is short, which can be used to cut high reflective rate materials like aluminum, copper, etc.

Its heat-affected zone is small, and the fabrication precision is high. However, the production of the excimer laser is expensive, the gas needs to be replaced frequently, and the operation cost is relatively high.

IV. Advantages of Laser Cutting Aluminum

Precision and accuracy in cutting

Laser cutting can achieve extremely high precision, which is one of its biggest advantages. Modern laser cutting machine’s positioning precision can be up to 0.02 mm, and width of slit width is smaller than 0.2 mm. This high precision makes laser cutting able to produce complex shapes, and precise sizes of aluminum parts, which can meet the high requirements in aerospace, electronics, and other industries.

What’s more, laser cutting can proceed repeatedly, which can cut the workpiece in the same way, further improving its precision and accuracy.

Clean edges and minimal material wastage

When laser cuts the aluminum, the melted material is blown away by high-speed airflow, and the cuts are flat and smooth, rarely generating burrs, and no need for second processing like grinding and other processes. The slit is narrow, small heat-affected zone, and high material utilization rate. Compared with traditional mechanical cutting, laser cutting can greatly reduce material waste, saving cost.

Versatility in creating intricate designs

Laser cutting features non-contact fabrication, and the laser head can move flexibly and cut any complex patterns.

Via programming control, laser cutting machines can cut various shapes of workpieces quickly and constantly, such as aluminum decorative parts on automobiles and electronic products, etc., offering wide design freedom. The flexibility of laser cutting also makes it become the ideal choice for making custom projects.

V. Limitations of Laser Cutting Aluminum

Heat affected zones and potential distortion

The heat affected zone generates surrounding the cuts when laser cuts. The material will undergo changes in its organizational structure and properties in this area.

The aluminum has good thermal conductivity, and heat affected zone is relatively large, especially apparently when thick sheets are cut.

Over large heat input may lead to aluminum deformation, affecting the component precision. Therefore, reasonably controlling the laser power and cutting speed is necessary, decreasing the heat-affected zone influence.

Surface quality issues

Although laser-cutting aluminum can acquire relatively smooth cuts, there are still some surface problems existence under some circumstances.

The cut surface may show defects such as streaks, roughness, and slag adhesion, especially when cutting thick aluminum plates or highly reflective aluminum alloys.

These defects will affect the appearance of the components and using properties. The cutting process parameters need to be optimized. And the cuts need to be handled like polishing, deburrs and so on.

Thickness constraints for efficient cutting

Laser cutting may have limitations in the aluminum thickness to some extent. Generally speaking, a high-power laser cutting machine can cut an aluminum sheet over 10 mm thick, but the cutting efficiency and quality will decrease.

Over 20 mm thick aluminum sheet is difficult to acquire satisfying cut quality via laser and probably needs other cutting methods. Besides, the type of aluminum also affects cutting thickness.

Pure aluminum has high reflectivity, which is difficult to cut, and high silicon aluminum limits the thickness that can be cut due to its low melting point.

VI. Applications of Laser-Cut Aluminum

Examples of industries using laser-cut aluminum parts

The application of laser-cut aluminum is widespread in various industries including aerospace, automotive manufacturing, electronic equipment, signage, and construction.

This technology offers a precise and highly effective method to cut the aluminum, ensuring cutting quality and consistency.

Creative design possibilities with laser-cut aluminum products

The creative design possibility of laser-cut aluminum is large. The laser cutting technology makes the metal fabrication sphere appear complex and artistic design.

Besides, the choice of surface treatment options of laser cutting decorating the metal sheet is multiple, allowing for designers and architects to achieve their creative designs, also these designs have persistence.

This demonstrates laser cuts are not only merely limited to functional component production, but also create works of art with aesthetic value.

Environmental benefits of laser cutting aluminum

The advantages of laser-cut aluminum lie in not involving the combustion or chemical process, apparently decreasing the emission of harmful pollutants.

Compared with traditional cutting machines, the modern laser cutting machine uses less electricity, reducing energy consumption.

Besides, laser cutting will not generate additional environmental costs and issues related to the chemical etching process.

These characteristics make laser cutting become an environmental metal processing method.

VII. Conclusion

In a nutshell, our passage talks about the significance of aluminum sheet processing, the factors that affect aluminum plates' laser-cutting properties, the characteristics and application spheres of different kinds of lasers cut aluminum, etc.

ADH Machine Tool is a professional manufacturer of processing laser cutting machines, that can help you improve production efficiency, optimize design, and enhance aluminum product quality. You can browse our official website for details or consult our salesmen.

Download the Infographic With High Resolution

Aquarium silicone sealant, Stainless steel special silicone sealant, Aquarium specific silicone sealant

Shandong Gufeng Technology Co., LTD. , https://www.gfkjgs.com