Joe Wang, Manager at Moldex3D Material Measurement Center

Demand for improved part performance has led to efforts to produce products that are lighter, stronger, and more efficient. In the last decade or so, FRP (fiber reinforced plastic) due to their superior mechanical performance and lightweight characteristics have been widely used in a variety of applications ranging from 3C products, automotive, shipbuilding, aerospace, and wind energy. The Resin Transfer Molding (RTM) is one of the most promising technologies available today. It belongs to one of the liquid composites molding (LCM) process. The RTM process is used in many applications since it is capable of making large complex three-dimensional parts with high mechanical performance, tight dimensional tolerance, and high surface finish. Furthermore, RTM is one of the most efficient and economical processes due to its capabilities such as non-expensive process equipment, closed mold process, low filling pressures, excellent control on mechanical properties, incorporation of metal inserts and attachments, and the possibility of producing large and complex parts and low labor costs.

However, there are still challenges facing the RTM industry. For example, it is difficult to accurately predict the resin flow because of locally high fiber volume in certain regions that can drastically change mold fill behavior. As such, RTM operators cannot accurately anticipate these effects, nor can they visually verify whether the part has reached full saturation before the injection process is shut down. If the part is not 100% impregnated, defects such as dry spots or voids are introduced, and the part must be discarded, and changes made to the injection geometry until all dry spots are eliminated. Applying this trial-and-error methodology to the resin transfer molding of large structures, i.e. utility-grade turbine blades, would be expensive. However, through successful CAE simulation of RTM flow, it is possible to predict the flow behaviors in a complex structure and eliminate the trial-and-error approach. Currently, RTM simulation software is still very rare, with huge market demand and potential customer base, including fiber materials manufacturers, mold manufacturers, and various industries that use RTM as a mean to produce their products. One critical parameter that affects the RTM CAE simulation quality is the permeability value of fiber mat. Permeability is the property of a porous medium (e.g. fiber mat) that is an indication of the ability for fluids (gas or liquid) to flow through that medium. High permeability will allow fluids to move rapidly through the medium. Traditional measurement methods such as vacuum-assisted resin transfer molding (VARTM ) require the sealing of a vacuum bag to an open mold in order to create a vacuum environment, a process that is not only painstaking but is also prone to human errors.

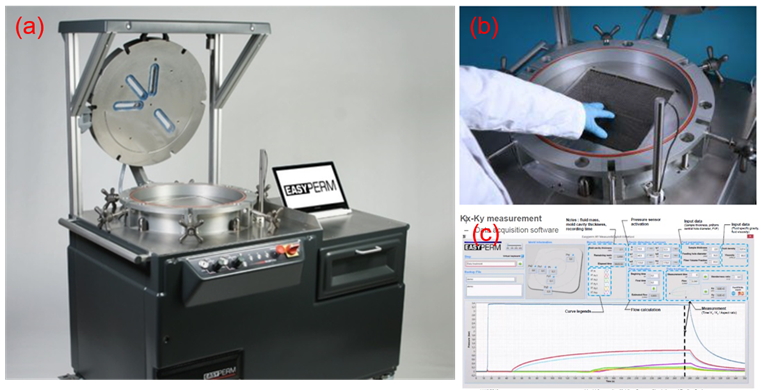

In light of this, Moldex3D introduced EASYPERM (Fig. 1) to its Material Research Center to boost its composite characterization capability. EASYPERM is a device used to measure the fabric permeability properties which won the JEC Invention Award in 2015. The instrument measures local pressure at different locations through the pressure sensors and characterize the in-plane and out-of-plane permeability. Fabric permeability is characterized by using the equilibrium flow rate and local pressures and then applying Darcy’s law to obtain permeability data.  In this study, we simulate oil filling behavior in the non-equilibrium stage of the permeability measuring process to verify the reliability of the simulation tool. In this stage, the system has not reached the equilibrium state and the local pressure increases from time to time. Through the pressure sensor, we can not only get the local pressure change with time but also the flow front arriving time.

Fig. 1 Photo of EASYPERM equipment (a), infusion mold (b), and data acquisition and analysis interface (c).

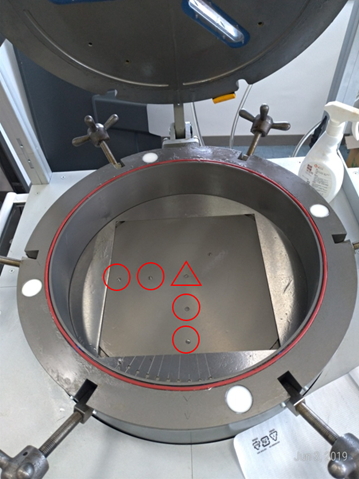

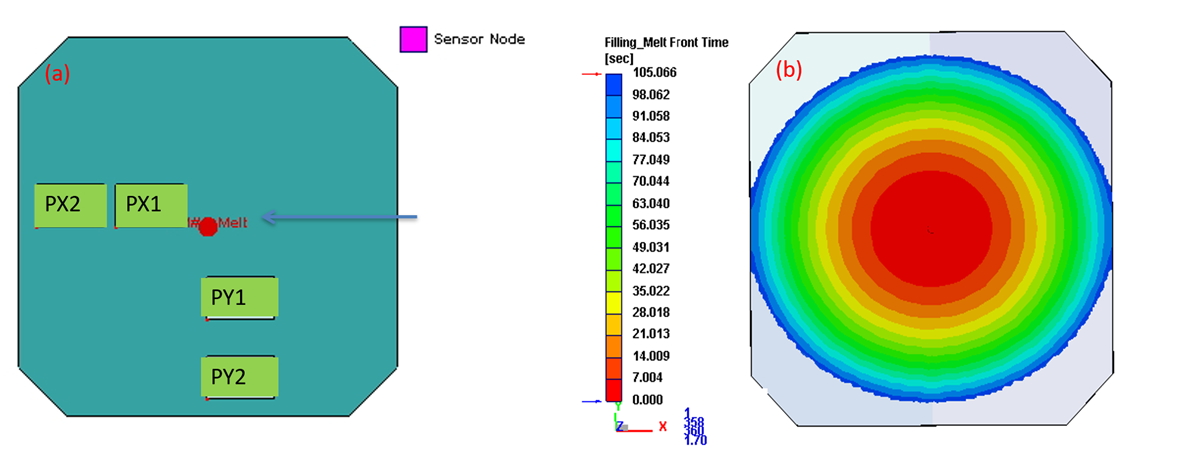

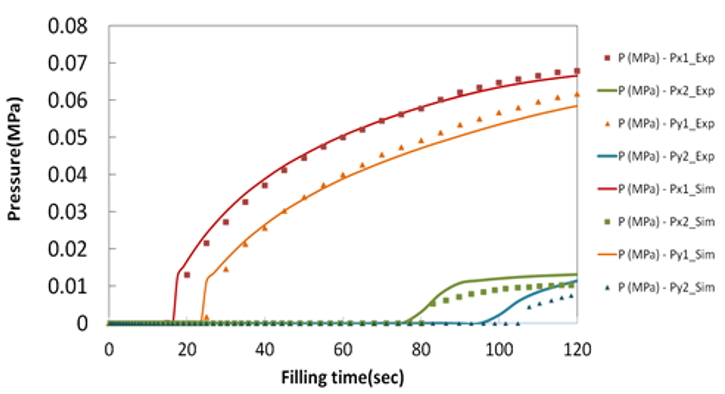

Through the pressure sensors (Fig. 2), we not only can obtain the local pressure change with time (transient pressure) but also the flow front arriving time. When the flow front arrives at the sensing point, the local pressure increases from zero. For Cross-Validation, we created an exact replicate of the EASYPERM cavity in the Moldex3D RTM module and used the same infusing experimental setting in the simulation. The verification case compares the arriving time and local pressure increasing trend between simulation and experimental results. Fig. 3 (a) shows the simulation melt front closely resembles the actual flow front. In this case, the results are very close (Fig. 4 and Table 1), demonstrating the accuracy of the RTM solver.Â

Fig. 2 The geometry of the in-plane cavity, pressure sensor locations (â–³ is the pressure sensor at the Origin; â—‹ is the pressure sensor at other in-plane locations)

Fig. 3 Simulation setting representing the actual infusing condition (inlet and pressure sensor locations) (a), and flow front time (b)

Fig. 4Â EASYPERM experimental data and simulation comparison. The data shows a good agreement between the experimental data and simulation that the pressure starts rising from zero when the melt front reaches the sensor nodes.

In RTM simulation, material properties such as the permeability of fiber mat play a significant role in the simulation accuracy. In the traditional VARTM measurement, permeability data accuracy and reliability are highly dependent on laboratory personnel. Because of this, Moldex3D has expanded our measurement capability to include the EASYPERM to better serve the simulation requirements and advance the composite industries.

FIBC PE Liners,Flexi Container Bags,Bulk Bag Unloading System,Big Bag Unloading System

Zhejiang Changying Plastic Packaging Products Co., Ltd. , https://www.cyfibc.com