I. Introduction

Press brakes are widely used in the sheet metal and manufacturing industries, but they also pose a significant threat to operators' safety. For one, by their design, press brakes are very dangerous machines, much more so without proper safeguarding equipment.

Injuries result because of unguarded access to the point of operation at the front of the machine and the operator’s ability to reach around the safety device to get to the point of operation at the side or back of the machine. Also, the backgauge system creates pinch points and poses a risk to the operator with its hazardous motion.

Every year, there are numerous accidents related to the use of press brakes. Unfortunately, many employers or users often neglect safety training for press brake operators, and many press brake manufacturers do not provide adequate safety protection devices.

The main hazard of using press brakes is that operators may bypass the safety guards and enter the machine's bending area. Additionally, the clamps and the rapid movement of the backgauge also pose a risk to operators.

Whenever a new press brake is installed, upgraded, or renovated, the risk factors associated with the press brake must be re-evaluated. The dwell time of mechanical and flywheel press brakes is relatively long, which cannot be reduced without the use of modern light curtain protection technology.

On the other hand, the stop time of hydraulic press brakes is shorter, allowing for the implementation of more protective measures. Here is the video for you to have a better understanding of the press brake safety:

II. Potential Press Brake Hazards

The common injuries that occur during press brake usage include crushing injuries and contact with the machine's operating points. These hazards can occur during various activities such as setting and adjusting the machine, bending with the press brake, cleaning machine blockages, lubricating the machine, and performing maintenance.

Other common hazards include touching the foot switch or foot pedal during operation, being crushed during bending, and injuries resulting from not properly closing relevant parts. Additionally, individuals may be pinched by the backgauge or injured while changing the punch and die.

Case Study

1. Finger Crush Accident

Imagine this scenario: an experienced press brake operator is processing a large workpiece. He is focused on the task at hand, ensuring each bend is precise and accurate. But then, the unthinkable happens. Due to the lack of proper safety devices, such as light curtains or pressure sensors, the operator's fingers accidentally enter the die area and are crushed by the upper die, resulting in fractures and tissue damage.

2. Ejected Work pieces

Another common risk is the accidental ejection or flying of workpieces from the die. This is more likely to occur when bending large workpieces without proper support devices. Imagine an operator bending a large metal sheet, but due to the lack of adequate support, as the press brake's ram descends rapidly, the workpiece suddenly springs out of the die like a giant spring, striking the operator's head and causing severe trauma.

III. Basic Safety Control Precautions

Before operating the bending machine, employees must undergo proper training to ensure their safety. The training should cover safe operating procedures, knowledge of the equipment and its protective devices, hazard identification, and emergency control measures.

Operators should be strictly supervised to ensure they follow established rules. It is important to wear personal protective equipment, such as gloves and goggles, before starting the bending operation.

The area around the machine should be kept clean and free of any obstructions that may interfere with the operation of the bending machine. It is also important to properly commission the machine to avoid malfunctions and contamination. During machinery bending, operators should remain alert and never leave the bending machine unattended.

IV. Safety Protection Equipment

1. Infrared Light Curtain Protection for Press Brakes

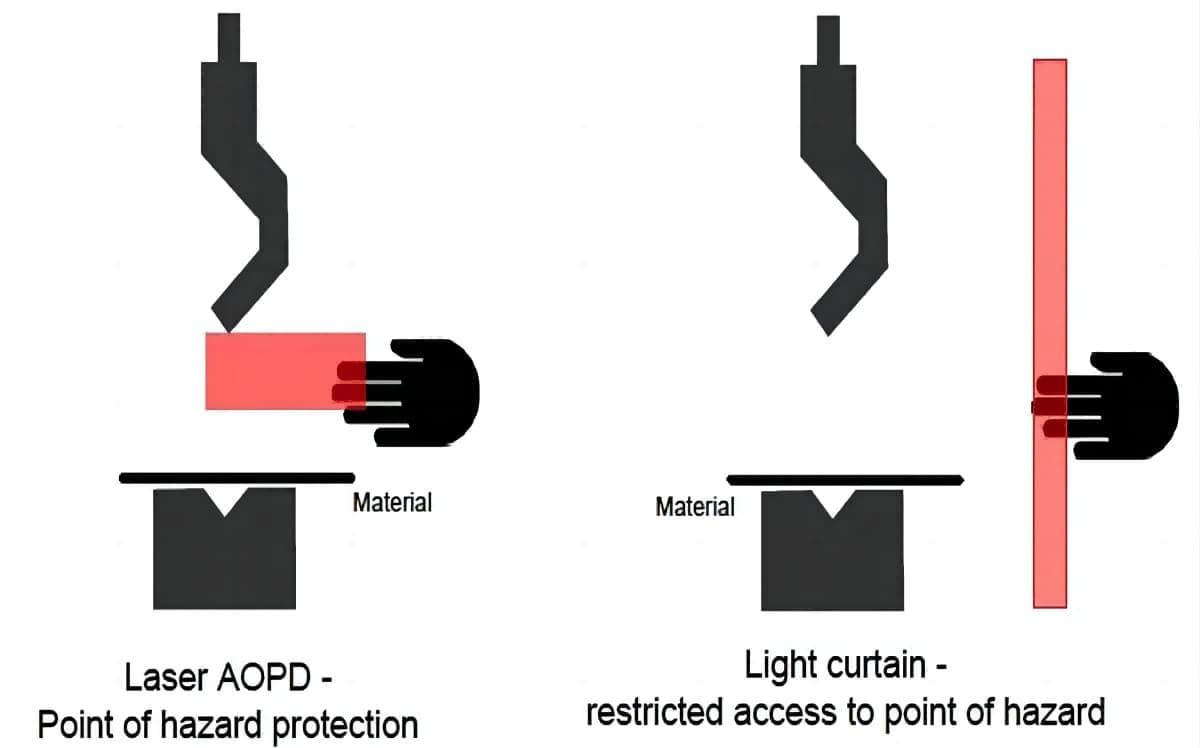

Infrared light curtain protection is a common safety device used in press brakes. The light curtain, initially designed as a product testing equipment, has since been adapted for machine protection.

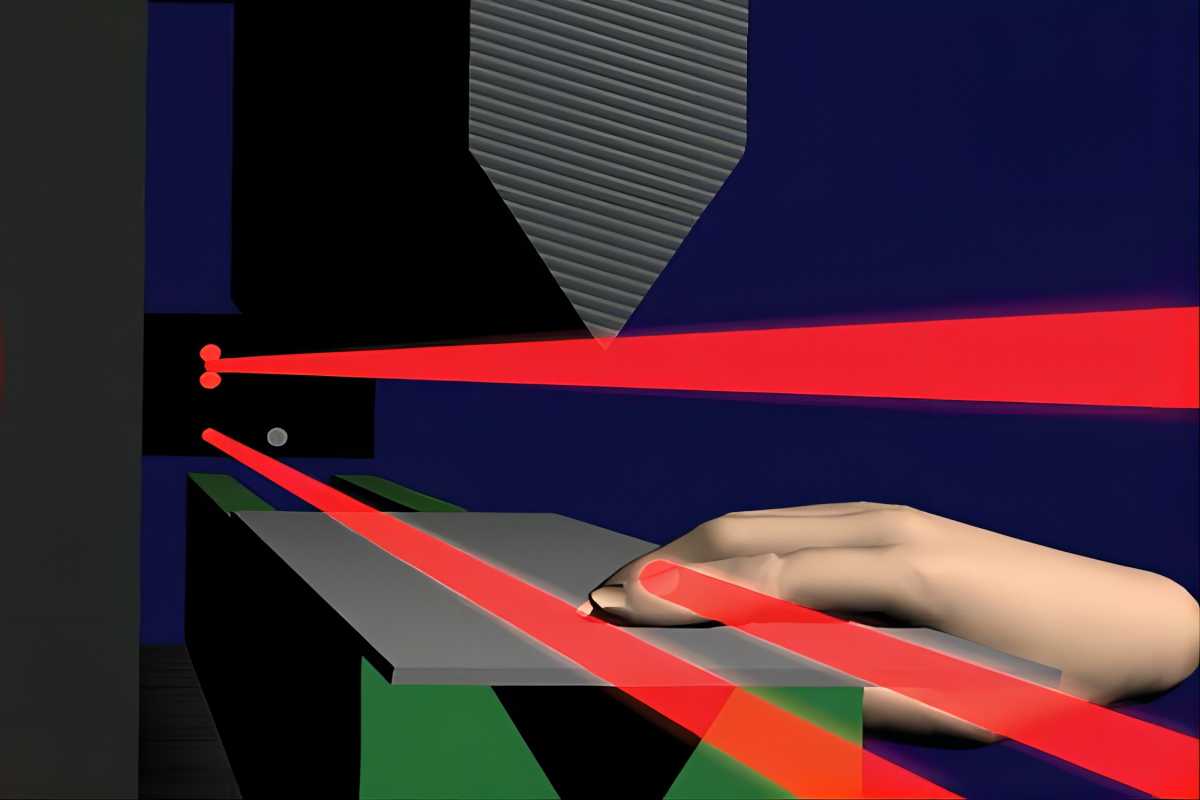

The light curtain is a photoelectric induction device that prevents human contact with dangerous areas. It can be installed near the toolings of a hydraulic press brake and consists of an emitter and a receiver.

The light curtain safety system may be connected to the safety monitoring relay and the magneto starter as it is part of the machine's control circuit. By creating a sealed protective area through an infrared beam, the light curtain protects both the operator and those nearby.

If an object, such as an operator's hand, passes through the work area, the press brake will stop bending or will not continue working until the object is removed. The LED transmitter and receiver of the light curtain detect the object and send an output signal upon interruption of the light plane.

However, the safe distance between the light curtain and the press brake is uncertain and may vary based on the installation, type, and emergency braking function of the light curtain. There is also a possibility of receiving incorrect signals during the bending process.

The light curtain is a common protective device used with press brakes and is a type of photoelectric induction equipment designed to prevent human contact with hazardous areas. It works by creating a sealed protective area near the toolings through an infrared beam.

If an operator's hand enters the work area, the press brake will stop bending or not continue working until the hand is removed. The light curtain provides protection not only to those in the working area but also to those near it. The safety distance between the light curtain and the machine depends on the application, the type of light curtain, and the machine’s stopping performance.

The light curtain system is connected to the safety monitoring relay and the magneto starter, and it is part of the machine control circuit. It starts the output signal when it senses an object, such as a worker or another object, interrupting the light plane.

Additionally, the light curtain has a function of automatically closing the system before the punch bends the workpiece. It also has a floating blank function that allows the bending stroke to continue without stopping.

On both sides of the press brake, the infrared beams emitted by the light curtain are synchronous and parallel. The light curtain can be programmed or non-programmable.

Programmable light curtains can input the flange of the workpiece into the program, which cancels the light beam blocked by the workpiece and allows the ram to reach the up dead point without stopping.

Non-programmable light curtains cannot cancel the interference light beam and may require the operator to close the light curtain, creating a danger. Finally, when bending very small workpieces, the operator experiences a greater risk of injury and needs to adjust them manually. This means the light curtain will not work when the operator is in front of the working area.

2. Two-Hand Control Device

A two-handed control device is an effective tool for protecting hands from injury. It consists of a vertical control device with two manual control buttons. For the machine to start, the operator must press both control buttons simultaneously.

If the buttons are not pressed, the machine will cease press brake operation. Once both buttons have been manually pressed and held, the machine stops when the mold reaches a certain position.

At this point, the operator can then feed the workpiece and use the foot switch instead of the manual control buttons to initiate the bending of the workpiece.

The two-handed control device allows the operator to feed the workpiece from a safe distance away from the operating point between the punch and die, thereby protecting the operator's hands from being hurt by the punch and die.

The purpose of this device is to prevent the operator's hands from coming into contact with the operating point while the machine is in operation.

3. Barrier Guards

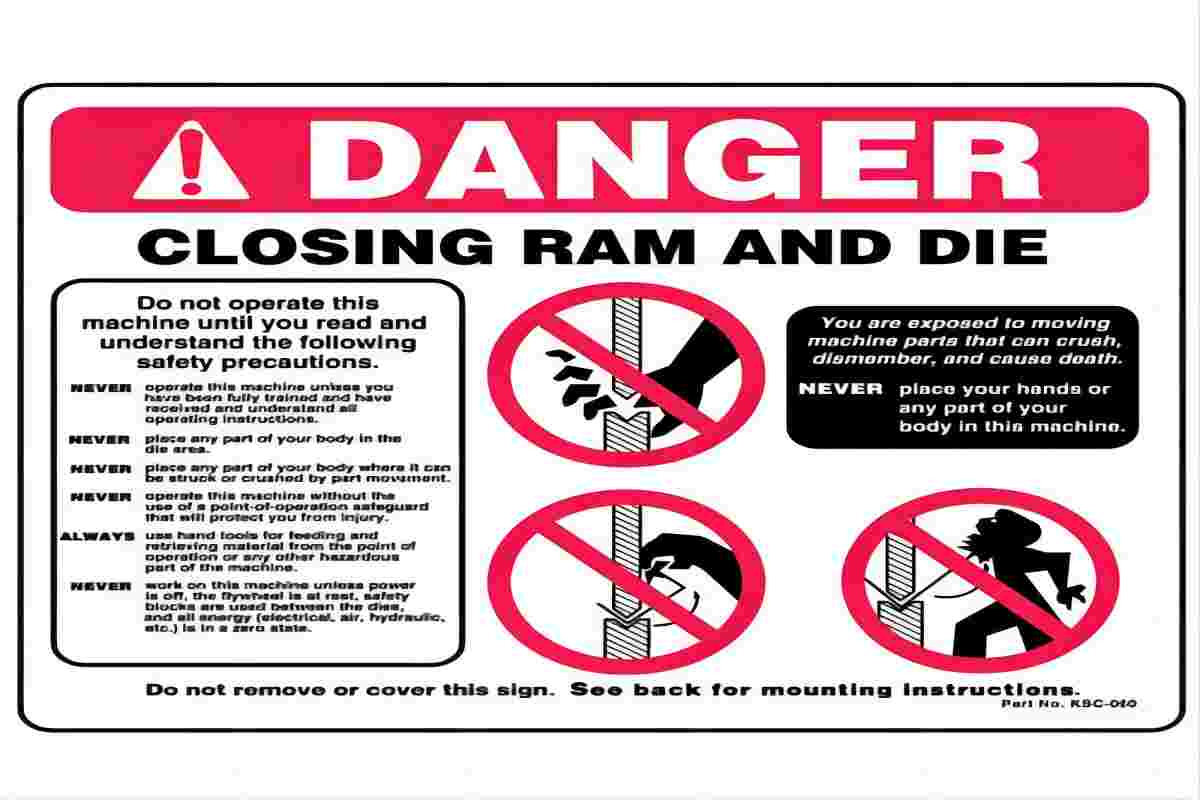

By OSHA’s definition, a guard must prevent people from reaching over, under, through, or around it. Guards must meet one of two measurement scales—the OSHA guard opening scale or the ANSI/CSA guard opening scale—to ensure that a small hand can’t reach far enough through any opening to get hurt.

The side guards of the press brake are movable barriers located on either side of the machine. These guards prevent the operator from entering the work area or reaching the rear gauge from either side, thereby protecting their hands from injury.

The rear guard blocks access to the machine from the rear, preventing the operator from coming into contact with the rear gauge. The press brake's housing and interlocking press barrier can also be positioned at a safe distance to prevent damage to the machine and injury to the operator from personnel or objects.

4. Installation Tools

There are potential hazards to the operator during the installation of tools, such as the tools unexpectedly falling and striking the operator's hand or the sudden movement of the machine ram.

Before installing the toolings or any other tools, it is necessary to lock the ram at the closed height position and raise it to the highest position. Before turning off the relevant switch, it is also necessary to adjust the position during the installation of other tools.

5. Safety rules about press brake tonnage

The tonnage of a press brake must be determined based on the thickness of the metal plate and the shape and size of the bend is made. This information can be found in the press brake tonnage table located on the machine.

It is important to avoid using excessive tonnage, as this can pose a danger to the operator and cause damage to both the workpiece and the machine. When the maximum tonnage is reached, the length of the workpiece should not be too short. It should extend at least one-third of the length of the workbench.

V. What safety method can best protect a press brake operator?

The Occupational Safety and Health Administration (OSHA) does not have specific machine guarding regulations for mechanically or hydraulically powered press brakes. However, these machines are generally classified under the General Duty Clause 1910.212, which covers failure to provide adequate protection to plant employees from known machine hazards. Typically, the industry follows industrial safety standards like the ANSI press brake standard, ANSI B11.3 for safe approach guidance, and ANSI B11.19 for design standards.

There are various ways to safeguard the operator of a press brake, which depend on the specific circumstances. For modern CNC press brakes, safety features such as light curtains and other sensing devices can be installed.

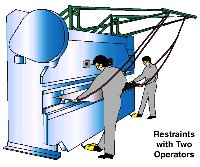

However, this is not an option for older mechanical press brakes. In such cases, pullbacks and restraints are used to prevent the operator's hand from reaching the point of operation. The pullback device requires the operator to wear a wrist strap that is connected to the machine. When the machine is activated, the operator's hand is pulled away from the operating area.

Before starting a new bending operation, the operator must visually inspect and adjust the pullback device to ensure that it will not interfere with the mold. The restraint system works by securing the operator's hand using an anchoring device and a wrist strap, preventing access to the point of operation.

Operators must have a clear understanding of different types of bending machines to better protect themselves from harm. The following are common bending machine safety features and precautions:

1. Mechanical Press Brakes

Safety Features:

- Mechanical Guards: Mechanical press brakes often come equipped with physical guards to prevent accidental contact with moving parts.

- Emergency Stop Buttons: Strategically placed emergency stop buttons allow operators to quickly halt the machine in case of an emergency.

- Two-Handed Controls: These machines typically require the use of both hands to operate, reducing the risk of accidental activation.

Safety Considerations:

- Regular Maintenance: Ensure that all mechanical components are regularly inspected and maintained to prevent malfunctions.

- Operator Training: Operators should be thoroughly trained in the specific safety protocols associated with mechanical press brakes.

- Clear Work Area: Keep the work area free of obstructions to avoid tripping hazards and ensure smooth operation.

2. Hydraulic Press Brakes

Safety Features:

- Hydraulic Overload Protection: These machines are equipped with overload press brake safeguarding systems to prevent damage and ensure safe operation.

- Light Curtains: Light curtains create a safety zone around the machine, stopping operation if the zone is breached.

- Pressure Relief Valves: These valves help manage hydraulic pressure, preventing potential overpressure situations.

Safety Considerations:

- Hydraulic Fluid Management: Regularly check and maintain hydraulic fluid levels to ensure optimal performance and safety.

- Leak Detection: Be vigilant for any signs of hydraulic fluid leaks, which can pose both safety and environmental hazards.

- Proper Lockout/Tagout Procedures: Follow strict lockout/tagout procedures during maintenance to prevent accidental machine activation.

3. Servo-Electric Press Brakes

Safety Features:

- Precision Control Systems: Servo-electric press brakes offer precise control over the bending process, reducing the risk of errors and accidents.

- Automatic Shutoff: These machines can automatically shut off if they detect any anomalies or unsafe conditions.

- Safety Interlocks: Safety interlocks ensure that the machine cannot be operated unless all safety conditions are met.

Safety Considerations:

- Electrical Safety: Ensure that all electrical components are properly insulated and maintained to prevent electrical hazards.

- Software Updates: Regularly update the machine's software to benefit from the latest safety features and improvements.

- Operator Familiarity: Operators should be well-versed in the specific safety features and operational protocols of servo-electric press brakes.

By understanding and implementing these safety features and considerations, operators can significantly reduce the risk of accidents and ensure a safer working environment when using different types of press brakes.

VI. Conclusion

Regular maintenance is necessary for safeguarding press brakes, and safety equipment must be worn while operating it. The press brake must be equipped with the appropriate safety devices and clear warning signs, which can not only keep the operators safe but also achieve maximum productivity.

The manufacturer of the press brake should provide operational training materials for their customers. Employers must provide professional pre-operation training for their operators and establish strict rules for operating the press brake.

ADH Machine Tool specializes in safety solutions for the metal working industry. From light curtains to laser scanners, we have the safety solution for your press brake or metal working application. Operating a press brake is a complex task, and special attention must be paid to safety considerations.

Programmable Sewing Machine,Swing Machine for Making Wing Pocket,Swing Machine for Making Toe Cap

Sichuan Kisae sewing machine Co.,Ltd. , https://www.kisaesew.com