I. Commissioning

Level the metal shearing machine.

Fill the hydraulic oil tank, open the cover to remove debris, clean the filter screen, and then refill the oil. The type of hydraulic oil to be used depends on the model and region.

Turn on the power supply, check the power indicator light, activate all emergency stop switches, start the oil pump, and verify that the motor is rotating in the correct direction.

The machine tool operates at a pressure of 25 Mpa. Adjust the machine pressure according to the thickness of the plate. Lubricate the hydraulic shearing machine according to the instructions indicated on the machine's label.

II. Troubleshooting Hydraulic Shear

1. Oil Circuit:

If the sheet metal shearing machine suddenly stops working and the blade does not move up or down, first check the machine and oil circuit (solenoid valve) and foot switch. If no faults are found in the circuit, disassemble the solenoid valve for cleaning.

2. Back Gauge:

If the two ends of the plate after shearing are inconsistent, check the back gauge connecting rod and see if the screws have fallen off or if the synchronous belt is slipping. Adjust the screw of the back gauge guide to bring both ends within the acceptable error range.

If the size of the cut material is different from the value displayed on the display, inspect the encoder that connects the flexible shaft to see if it is torn or if the screws are loose. If the connecting flexible shaft is damaged, replace it and then calibrate the value of the back gauge.

3. Noise

The machinery produces noise during operation. Check the motor oil pump for any potential noise. Also, check the noise of the oil cylinder and return cylinder.

If the machine makes a squeaking sound, check whether the ball head of the return cylinder is low on oil and if the cylinder ball head requires oil. If the pressing cylinder lacks force, add nitrogen at 6-8 MPa.

4. Adjustment of Blade Edge Clearance

If the blade edge is dull or the blade is not sharp, turn over the blade or it can be replaced in time. When adjusting the blade edge, first set the blade edge clearance to the maximum, then gradually decrease it by closing the ball valve.

At this point, the upper and lower blades should be on the same plane. Use a feeler gauge to measure the blade gap between the blade edges and adjust it through the blade-adjusting screws located on the workbench.

4.1 Blade Wear

Symptoms: The edges of the sheared sheet metal are uneven, with burrs or cracks.

Cause: The blade has been used for a long time, causing the edge to become dull or chipped.

Solution:

- Inspect Blade Condition: Regularly check the sharpness and integrity of the blade.

- Sharpen the Blade: Use professional sharpening equipment to grind the blade, ensuring a sharp edge.

- Replace the Blade: If the blade is severely worn and cannot be restored by grinding, it should be replaced with a new one.

4.2 Improper Blade Clearance

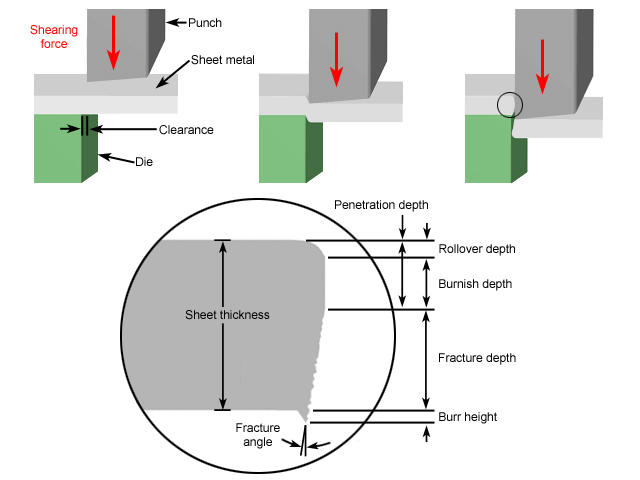

Symptoms: The edges of the sheared sheet metal are significantly deformed or have irregular cuts.

Cause: The blade clearance is improperly adjusted, leading to uneven distribution of shearing force.

Solution:

- Adjust Blade Clearance: Adjust the blade clearance according to the thickness of the sheet metal. Generally, the blade clearance should be 5-10% of the sheet metal thickness.

- Use a Clearance Gauge: the shearing machine uses a professional clearance gauge to measure and adjust the blade clearance, ensuring uniformity.

4.3 Incorrect Blade Installation

Symptoms: Abnormal noise or vibration occurs during shearing, and the cutting quality is unstable.

Cause: The blade is not securely installed or is incorrectly positioned, causing the blade to wobble during shearing.

Solution:

- Check Blade Installation: Ensure the blade is securely installed and the bolts are tightened properly.

- Correct Blade Position: Use professional tools to correct the blade position, ensuring the upper and lower blades are parallel and the clearance is uniform.

5. Electrical System

Symptoms: The shearing machine cannot start or operates unresponsively.

Cause: Electrical control system faults, such as broken circuits, poor connections, or controller failures.

Solution:

- Check Electrical Circuits: Inspect electrical circuits for any breaks or poor connections.

- Test the Controller: Use professional equipment to test the controller's working condition, and replace it if necessary.

- Check Terminal Connections: Ensure all terminal connections are secure, with no looseness or oxidation.

6. Insufficient Hydraulic System Pressure

Symptoms: Insufficient shearing force, stuttering during shearing, or inability to complete the precision cut.

Cause: Insufficient hydraulic system pressure or contaminated hydraulic oil.

Solution:

- Check Hydraulic Oil: Regularly check the cleanliness and level of the hydraulic oil, and replace it if necessary.

- Clean the Oil Filter: Regularly clean or replace the oil filter to ensure the hydraulic system is clean.

- Inspect the Hydraulic Pump: Check the working condition of the hydraulic pump to ensure it can provide sufficient pressure.

III. What Is Shearing Machine

A plate shearing machine is used to cut metal plates into sheets or strips, which is widely used in the sheet metal processing industry. It features a movable upper blade and a fixed lower blade, which are driven by a power device to cut the metal plate at a set gap.

The two main types of shearing equipment are hydraulic swing beam and guillotine shearing machines, which vary in blade type and material compatibility.

IV. Preventive MaintenanceÂ

1. Regular Maintenance and Inspections

1.1 Daily Inspections

- Cleaning: Clean the shearing machine daily, removing dust, debris, and metal shavings to keep the machine tidy.

- Lubrication: Add lubricating oil as required by the lubrication chart, ensuring all moving parts are adequately lubricated.

- Blade Inspection: Check the sharpness and installation of the blades daily to ensure they are not damaged or worn.

1.2 Weekly Inspections

- Lubricate Moving Parts: Lubricate bearings, gears, and sliding parts weekly to reduce friction and wear.

- Hydraulic System Check: Inspect the hydraulic oil level and cleanliness, ensuring the hydraulic system operates correctly. Check hydraulic hoses and connections for leaks or wear.

1.3 Monthly Inspections

- Detailed Inspection: Conduct a thorough inspection of key components (such as blades, hydraulic system, and electrical connections) monthly, addressing any issues promptly.

- Adjust Blade Clearance: Adjust the blade clearance according to the thickness of the sheet metal to ensure cutting quality.

2. Cleaning and Alignment

2.1 Machine Cleaning

- Maintain Cleanliness: Regularly clean the shearing machine, removing dust, debris, and metal shavings to prevent accumulation that could affect machine efficient performance.

- Rust Prevention: Apply rust preventive grease to unpainted parts to prevent rust.

2.2 Blade Alignment

- Check Alignment: Regularly check and adjust blade alignment to ensure precise cutting.

- Adjust Alignment: Adjust blade alignment as needed to maintain cutting efficiency and machine longevity.

3. Professional Maintenance

3.1 When to Seek Professional Help

- Complex Issues: For complex common problems or significant damage, seek help from professional technicians or the manufacturer to ensure accurate diagnosis and effective repairs.

- Service Agreements: Consider establishing a service agreement with the manufacturer or authorized service provider, including regular inspections, maintenance, and priority support to keep the machine in optimal condition.

V. Conclusion

Debugging and troubleshooting of the metal shearing machine encompasses checks of the oil cylinder, oil circuit, and electric back gauge, as well as addressing issues such as noise and blade clearance adjustments in metal fabrication. The quality of the shearing machine also plays a role in the cost of repairs and maintenance and maintaining optimal productivity.

By choosing the ADH manufacture, you can benefit from time and cost savings, as well as receive high-quality after-sales service. Contact us for more information about our shearing machines.

Batch Pre Expander Foaming Machine,Polystyrene Foam Making Machine,EPS Expandable Polystyrene Machine,EPS Batch Pre Expander

Hangzhou Sutuan Machinery Co.,Ltd.

Leading EPS EPP ETPU machinery manufacturer , https://www.sutuanmachinery.com